Product Search

Solution Search

Searchable by product name, product model or standard.

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

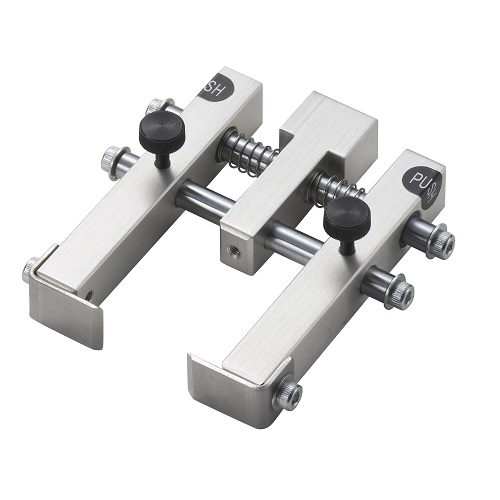

90 degree Peel Test Fixture

P90-200N

Description Add to favorites

Feature

- Ideal for 90 degree peel test of adhesives such as tapes, glue, stickers etc.

- Standard type (P90‐200N) and economy type (P90-200N-EZ) available

- Complies with the corresponding part of IEC, ISO, ASTM, JIS, etc. (only for P90-200N)

Relevant Industrial Standards

IEC 249-1 [ 1982 ] [Base materials for printed circuits. Part 1: Test methods] (corresponding part only)

IEC 326-2 [ 1990 ] [Printed boards. Part 2 Test methods] (corresponding part only)

ISO 29862 [ 2018 ] [Self adhesive tapes-Determination of peel adhesion properties] (corresponding part only)

ASTM D6862-11 [ 2016 ] [Standard Test Method for 90 Degree Peel Resistance of Adhesives] (corresponding part only)

JIS Z0237 [ 2022 ] [Testing methods of pressure-sensitive adhesive tapes and sheets] (corresponding part only)

Relevant Information and Materials

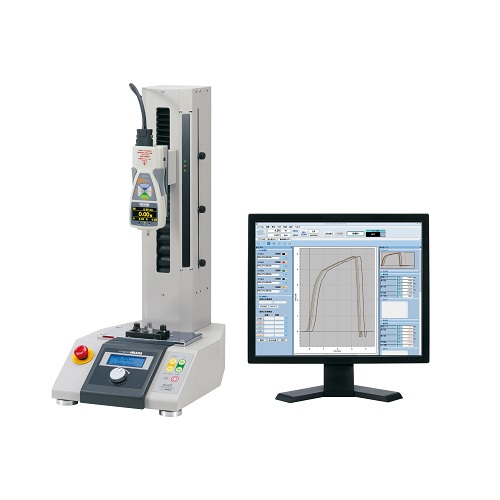

Example of Product Configuration

P90-200N

Features

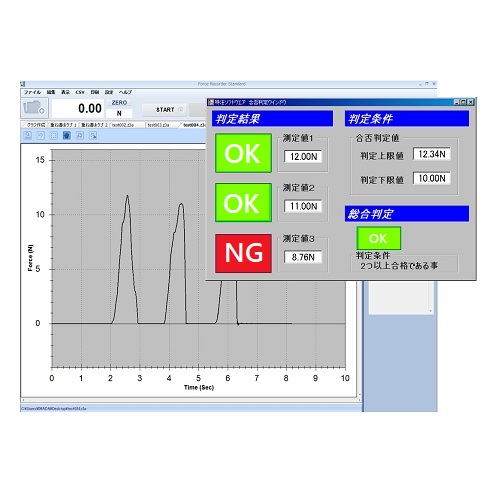

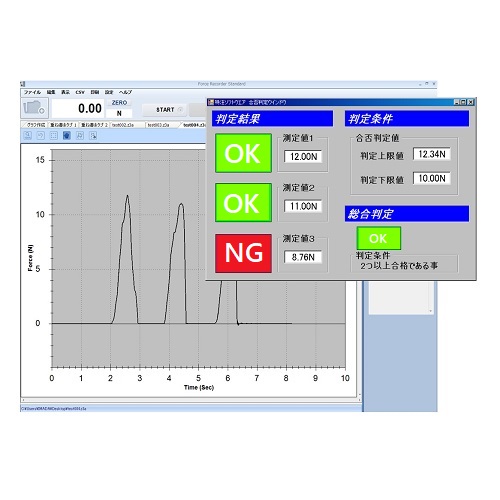

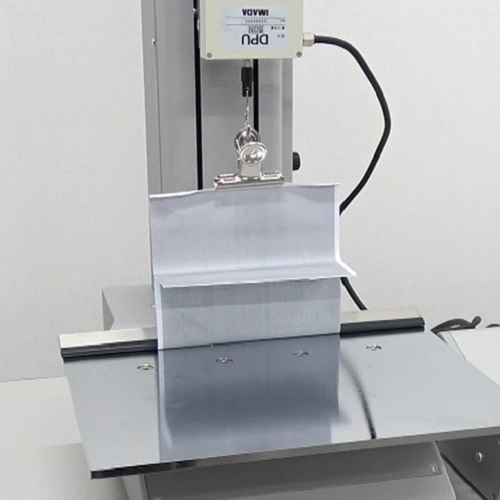

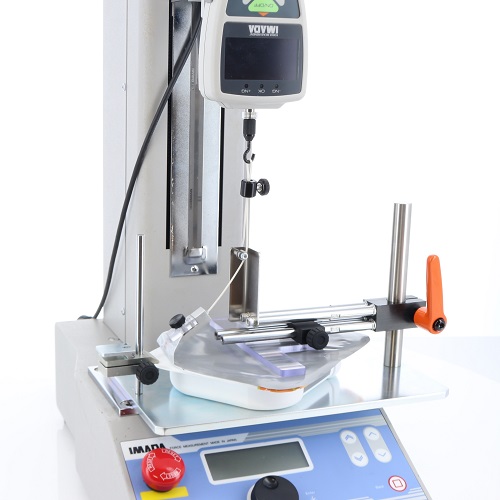

This testing system is designed for 90 degree peel (adhesion) test of such as tape.

The capacity is up to 200N.

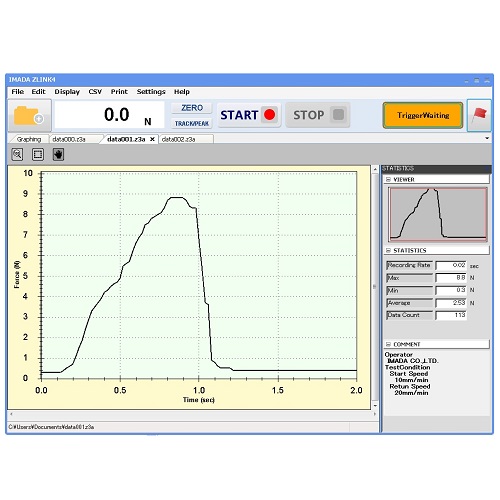

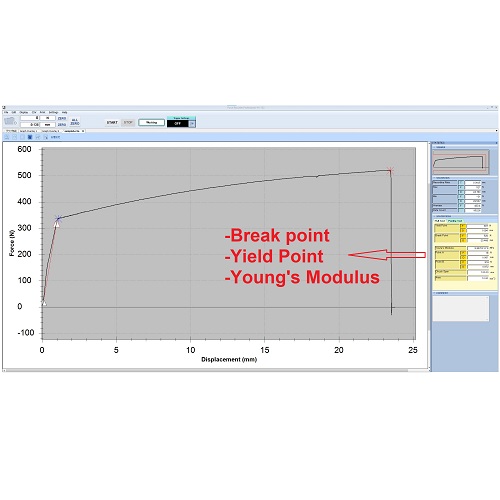

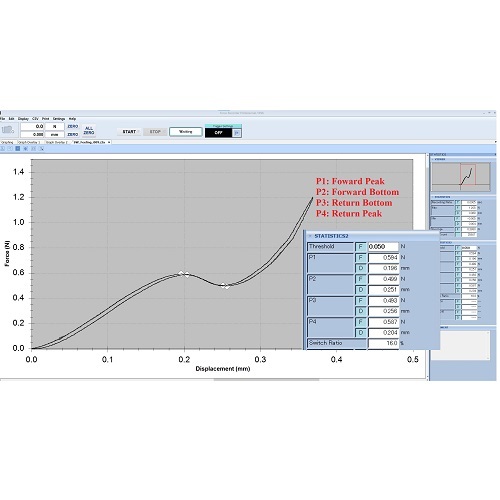

The statistic, such as average value, is calculated and converted to unit of adhesive strength by the graphing software.

inquiry number

1P2003A

Present the “inquiry number” below when you contact us, for prompt assistance.

Product used

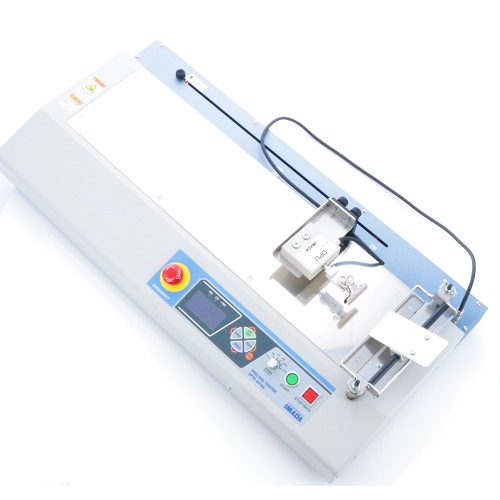

Force-Displacement unit

FSA-0.5K2-200N

1

Downloadable Graphing Software Option

-NEXT

1

Optional Attachment

P90-200N

1

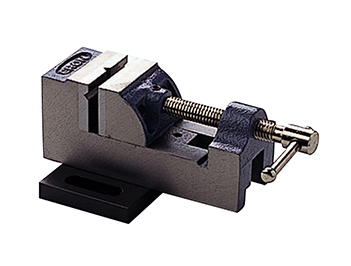

Optional Attachment

FC-20

1

Download Card Advanced

Peel Testing Module 1

1

Relevant Industrial Standards

IEC 249-1 [ 1982 ] [Base materials for printed circuits. Part 1:Test methods] (corresponding part only)

IEC 326-2 [ 1990 ] [Printed boards. Part 2 Test methods] (corresponding part only)

ISO 29862 [ 2018 ] [Self adhesive tapes-Determination of peel adhesion properties] (corresponding part only)

ASTM D6862-11 [ 2016 ] [Standard Test Method for 90 Degree Peel Resistance of Adhesives] (corresponding part only)

ASTM D3330 [ 2010 ] [Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape] (corresponding part only)

Cautions

A purchase of download cards and a prior user/product registration on IMADA Connected are required to download Force Recorder Next series and chargeable additional functions.

The sample can not be peeled fully if its elongation rate is over 210%.

If your sample width is over 20mm, you may need another wide model of film grip.

Refer to specifications of each product for details.

Product configuration varies depending on the shape and characteristic of the sample, and measurement conditions.

The recommended capacity of measurement instruments varies depending on the expected force to be loaded.

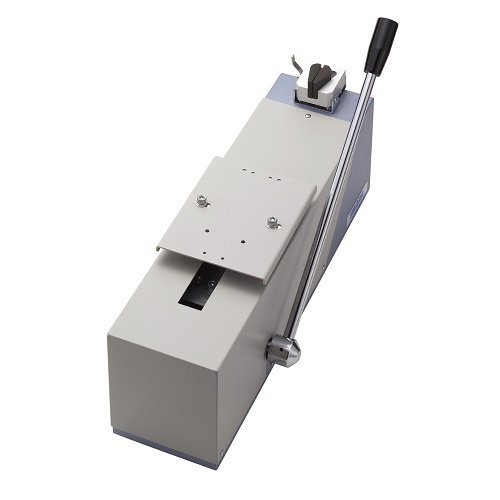

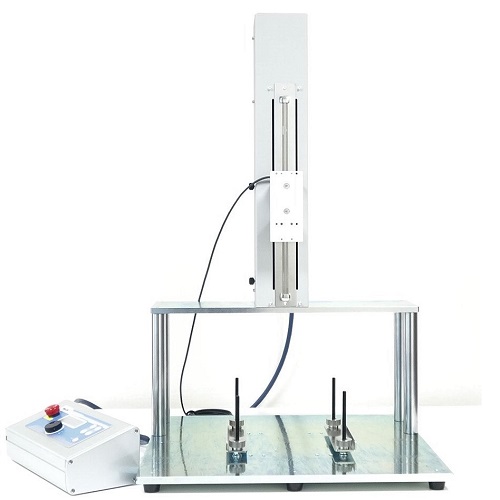

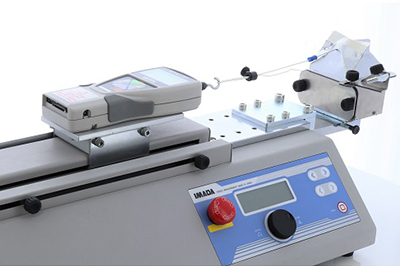

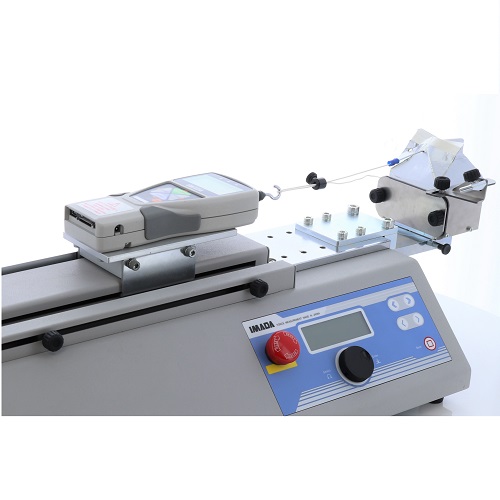

P90-200N-EZ

Features

This testing system is designed for 90 degree peel (adhesion) test of such as tape.

It offers a simple solution of peel test up to 200N.

inquiry number

1P2004A

Present the “inquiry number” below when you contact us, for prompt assistance.

Product used

Digital Force Gauge

DST-200N

1

Motorized Test Stand

MX-500N

1

Optional Attachment

P90-200N-EZ

1

Optional Attachment

FC-20

1

Cautions

To ensure enough peel length, long stroke model of motorized test stand is recommended.

The sample can not be peeled fully if its elongation rate is over 210%.

If your sample width is over 20mm, you may need another wide model of film grip.

Refer to specifications of each product for details.

Product configuration varies depending on the shape and characteristic of the sample, and measurement conditions.

The recommended capacity of measurement instruments varies depending on the expected force to be loaded.

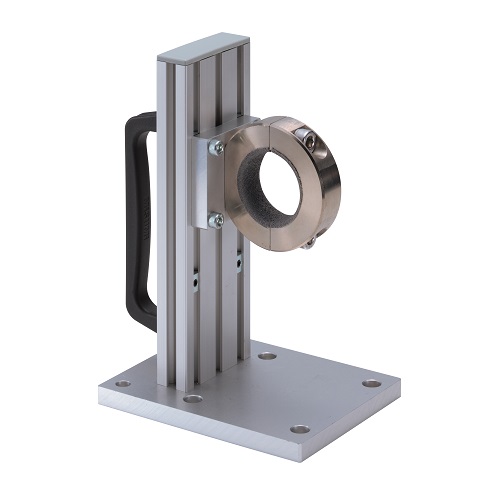

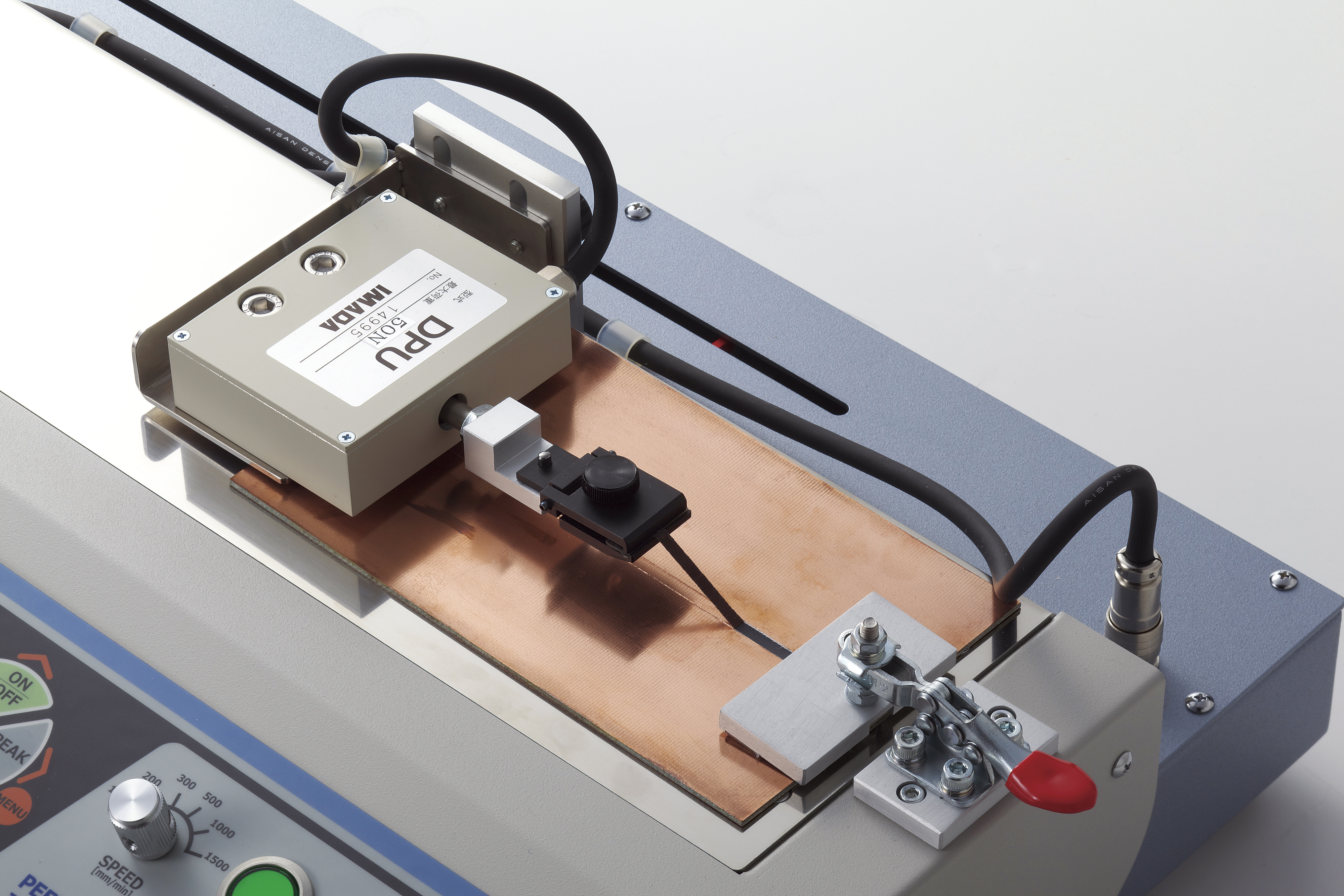

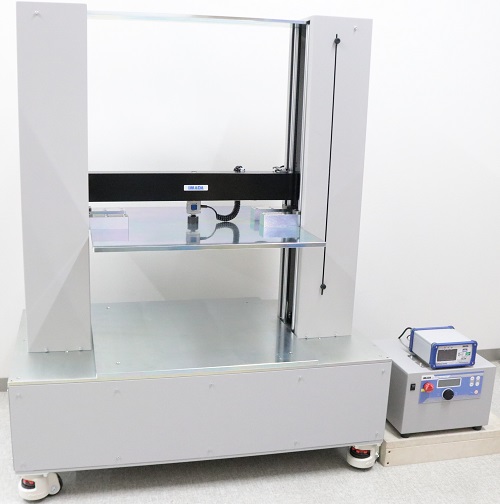

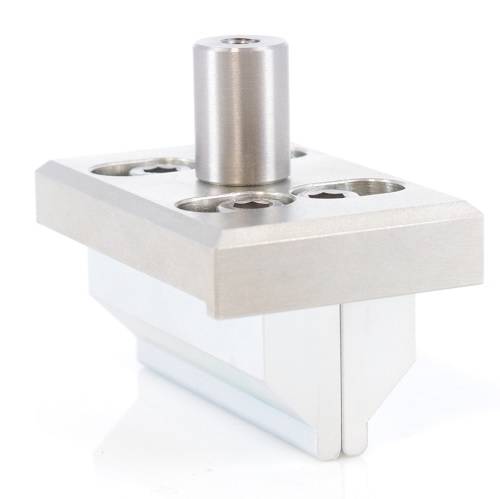

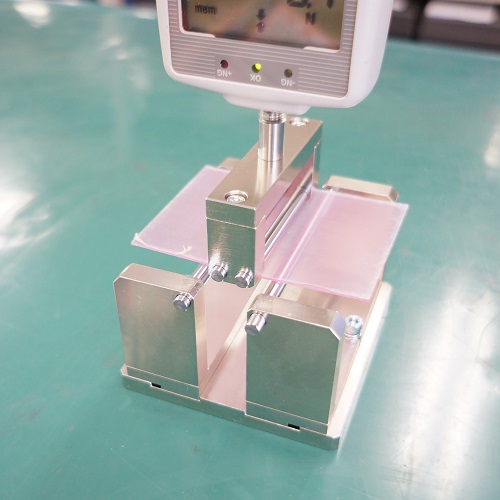

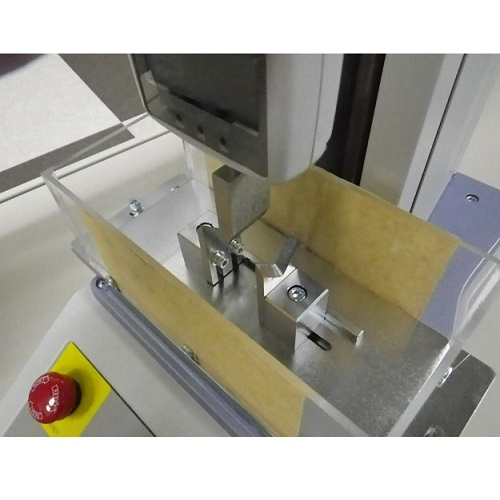

P90-200N-BB

Features

90 degree peel test of adhesives fixing samples with a breadboard and clamps such as printed circuit board.

Up to 200N.

The average value is automatically calculated by the graphing software.

inquiry number

1P2006A

Present the “inquiry number” below when you contact us, for prompt assistance.

Product used

Digital Force gauge

ZTS-200N

1

Motorized Test Stand

MX2-500N

1

Optional Attachment

P90-200N-BB

1

Optional Attachment

FC-21U

1

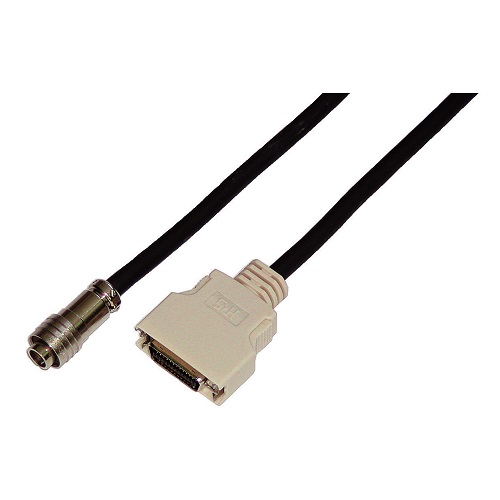

Optional Cable

CB-528

1

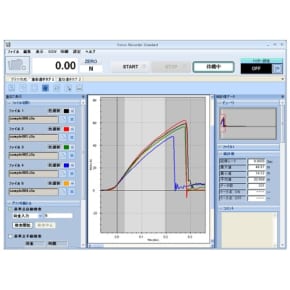

Optional software

Force Recorder Standard

1

Relevant Industrial Standards

IEC 249-1 [ 1982 ] [Base materials for printed circuits. Part 1:Test methods] (corresponding part only)

IEC 326-2 [ 1990 ] [Printed boards. Part 2 Test methods] (corresponding part only)

JIS C5016 [ 1994 ] [Test methods of copper-clad laminates for flexible printed wiring boards] (corresponding part only)

ISO 4525 [ 2003 ] [Metallic coatings-Electroplated coatings of niclel plus chromium on plastics materials] (corresponding part only)

JIS H 8630 [ 2006 ] [Electroplated coatings on plastics materials for decorative purposes] (corresponding part only)

Cautions

To ensure enough peel length, long stroke model of motorized test stand is recommended.

Wide width model of film grip is necessary if the sample width is over 20mm.

Refer to specifications of each product for details.

Product configuration varies depending on the shape and characteristic of the sample, and measurement conditions.

The recommended capacity of measurement instruments varies depending on the expected force to be loaded.

Relevant Products

Measurement Example Videos

User Guide Videos

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

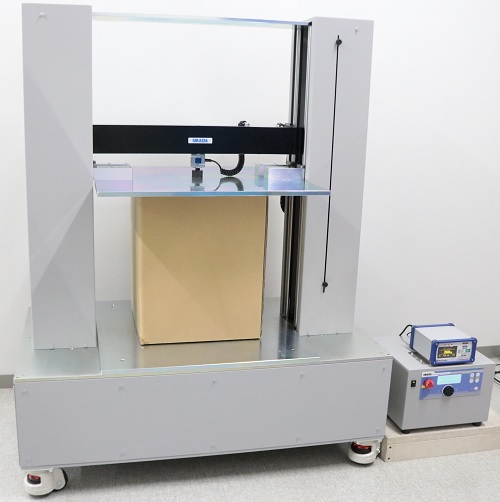

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

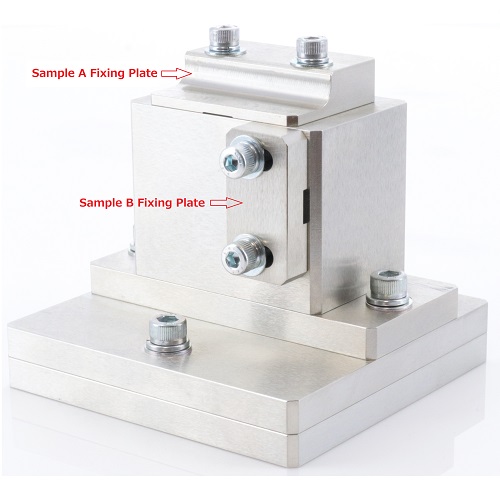

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

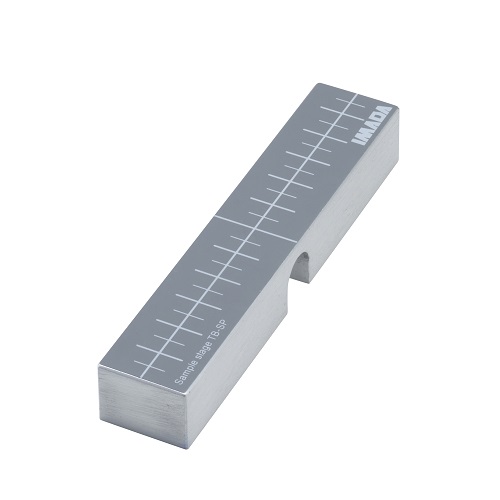

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

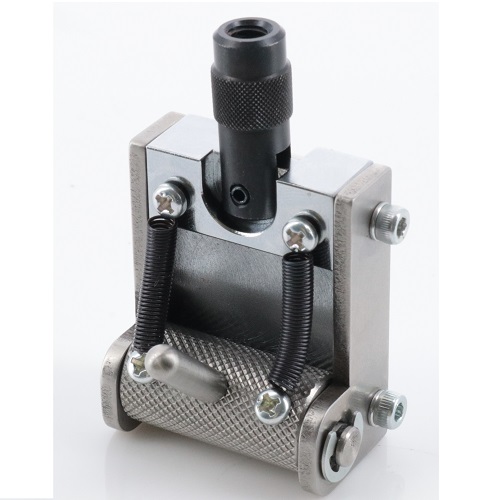

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

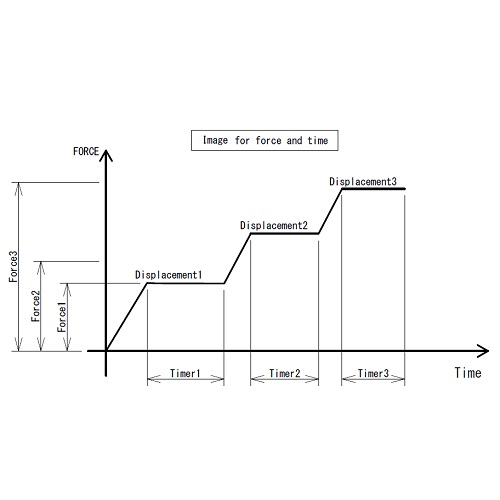

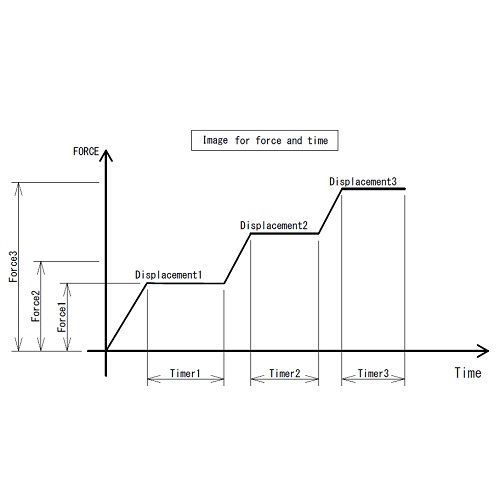

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

.png)