Product Search

Solution Search

Searchable by product name, product model or standard.

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

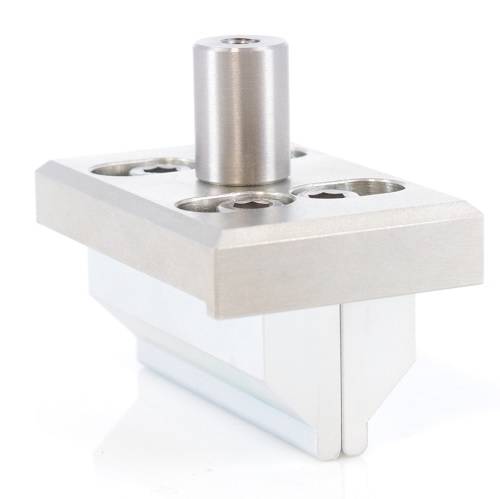

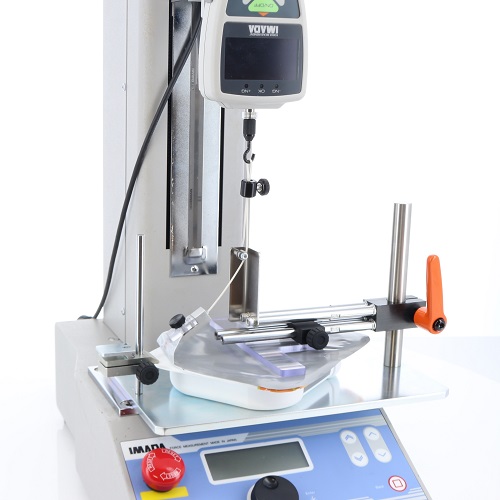

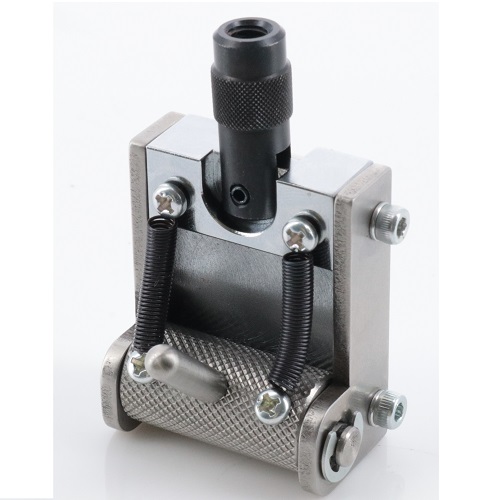

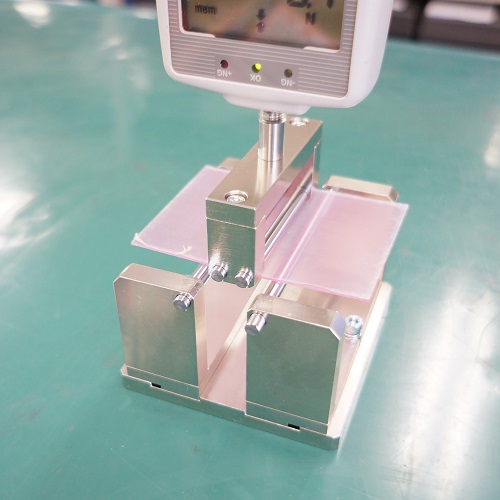

Pull-off Test of Coating (Complies with the corresponding part of ISO 4624: 2002)

- Force Measurement IMADA

- SOLUTIONS

- Peel Test

- Pull-off Test of Coating (Complies with the corresponding part of ISO 4624: 2002)

Description FAVORITES

Other Peel

ISO

JIS

Graph

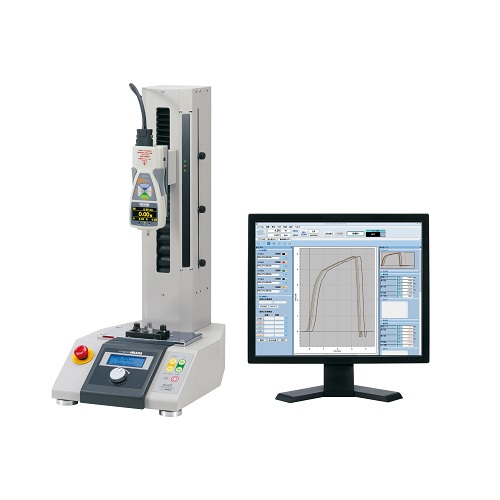

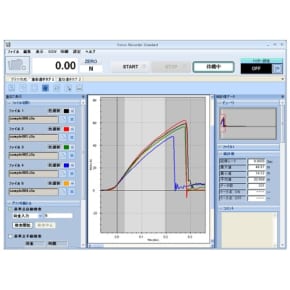

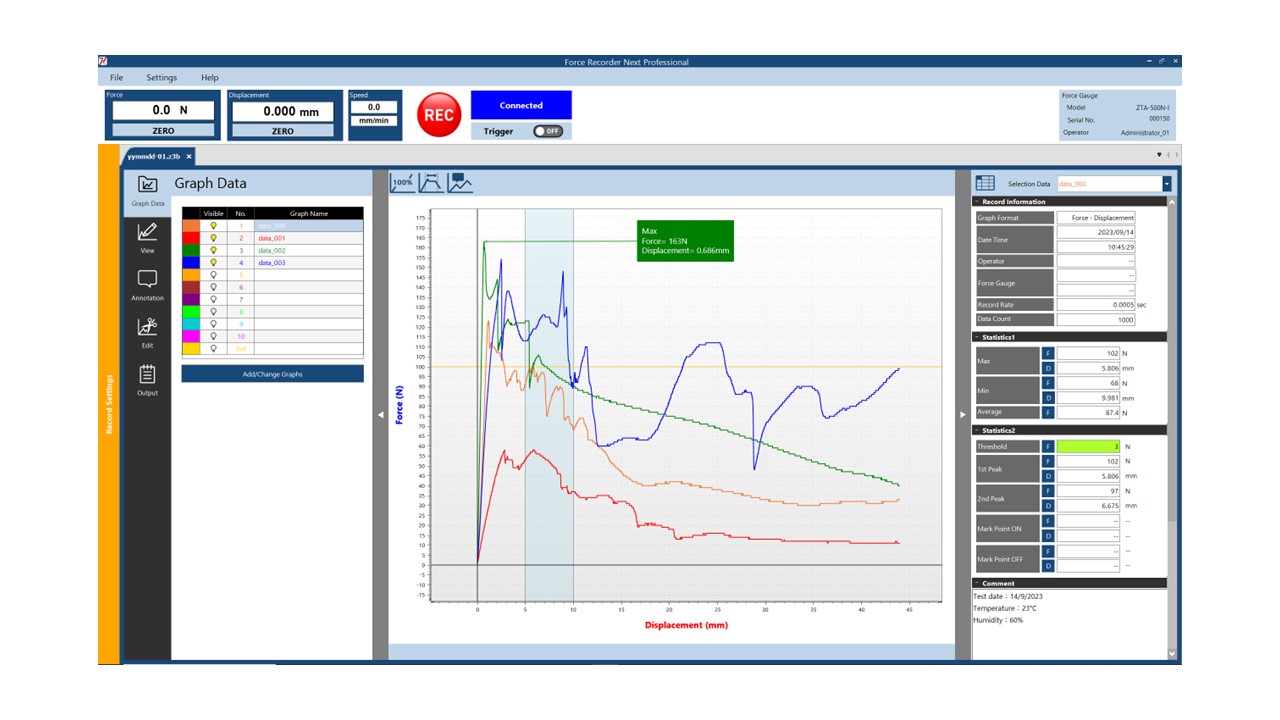

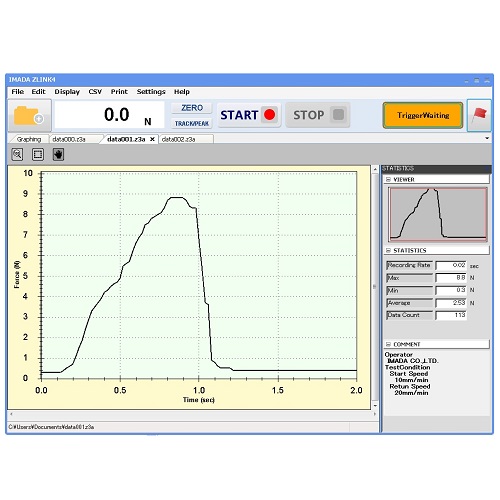

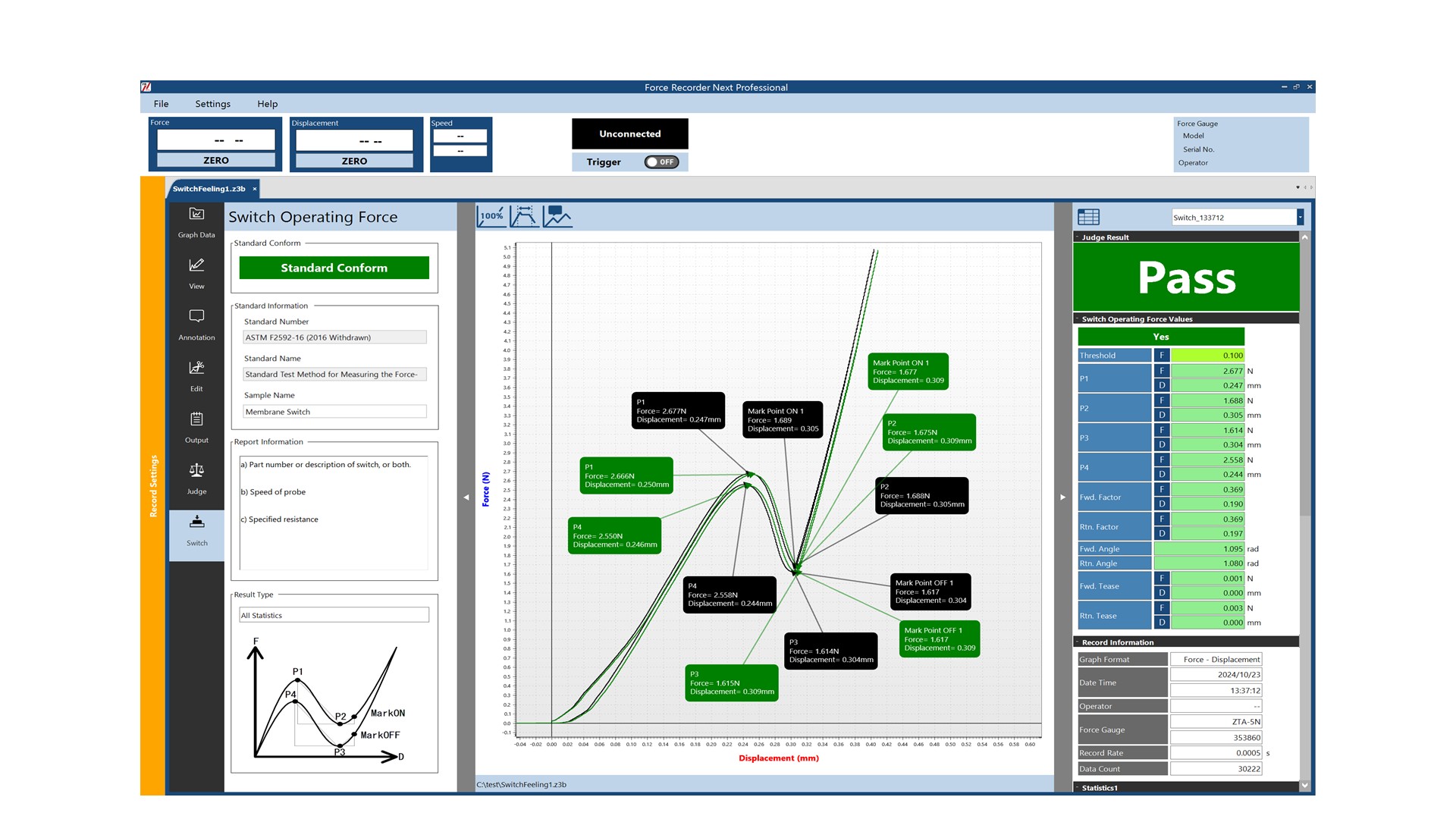

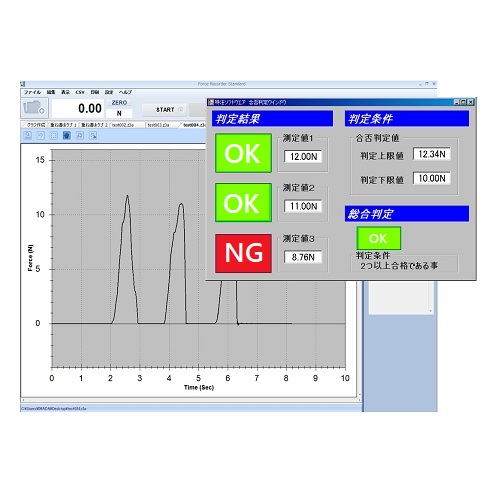

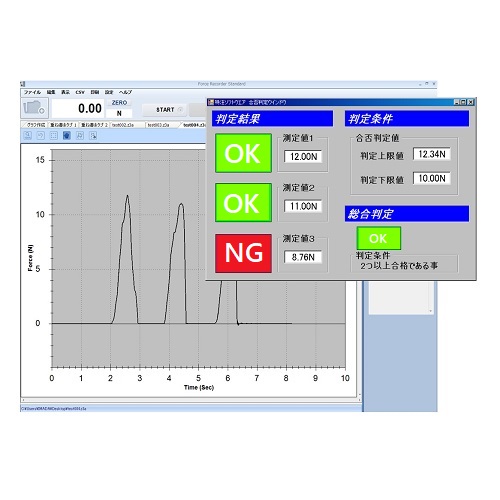

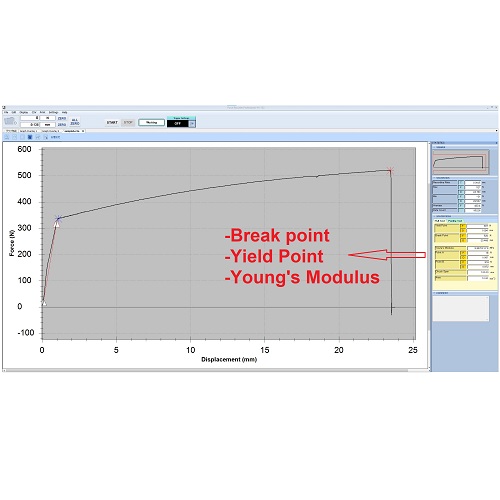

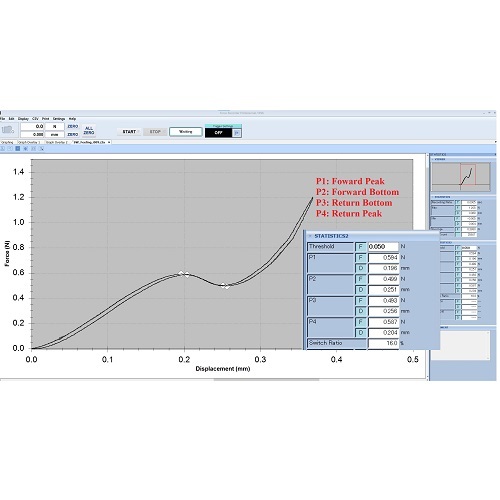

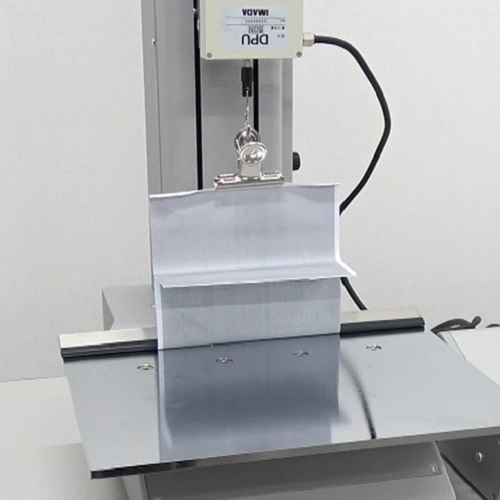

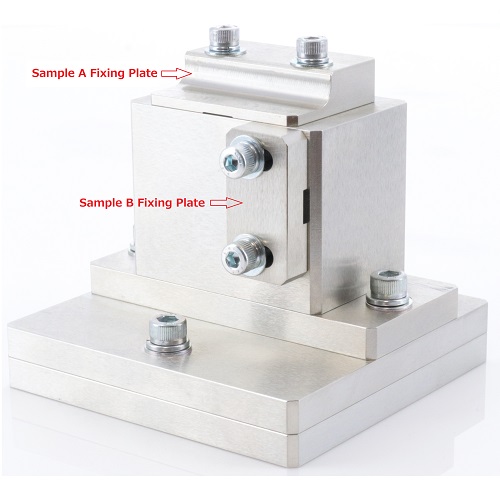

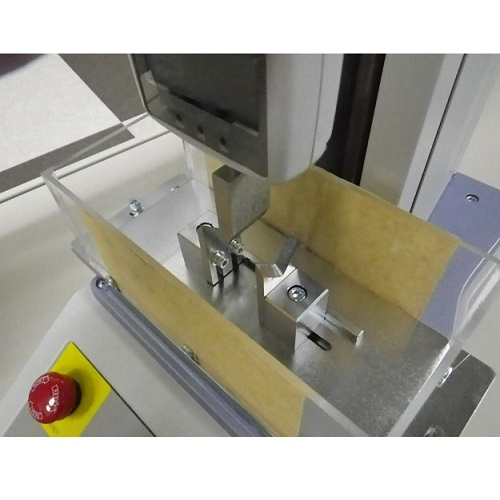

This is pull-off test for adhesion of coating.This video introduces testing complying with ISO 4624: 2002 Paint and varnished - Pull-off test for adhesion. As per a requirement of the standard, tensile force is applied perpendicularly to the coated surface to be pulled off within 90 seconds at the speed of which does not exceed 1MPa/s. The force value required to pull off the coating is recorded as the test result. Pull the adhered dolly until the sample breaks and obtain the maximum force value. This maximum value is converted to MPa to calculate the breaking strength. IMADA graphing software graphs the relationship between force and time during the test to confirm whether the requirements are met. It also visualizes the load transition for fracture. In addition, with high-speed sampling of 2000 data per second, IMADA force gauge used in this test captures accurate maximum force value. Test 6 or more samples and show the average, maximum and minimum fracture strengths calculated as a result. Watch the video for test details. The tests in this standard ISO 4624: 2002 are used in R&D and quality control.

inquiry number

1T2005A

Present the “inquiry number” below when you contact us, for prompt assistance.

Relevant Industrial Standards

ISO 4624 [ 2002 ] Paint and varnished - Pull-off test for adhesion (corresponding part only)

JIS K5600-5-7 [ 2014 ] [Testing methods for paints-Part 5: Mechanical property of film- Section 7: Adhesion test (Pull-off method)] (corresponding part only)

Related sample

- Paint

- Glue

- Coating

- Varnish

Measurement Example Videos

Cautions

Adhesive is not included.

Sample size is smaller than 50 x 100 ㎜.

This video shows the testing image of objective sample. Some samples may not be suitable to measure with this configuration depending on their materials or shapes.

The example of product configuration is for your reference only. It varies depending on sample, measurement method and testing capacity.

The products used in this video may differ from the example of product configuration.

Please select the right product model for the product configuration. Refer to the specification of each product for the compatibility.

Relevant Videos

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

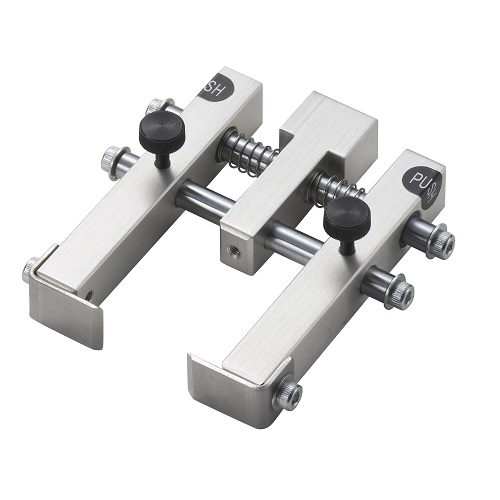

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

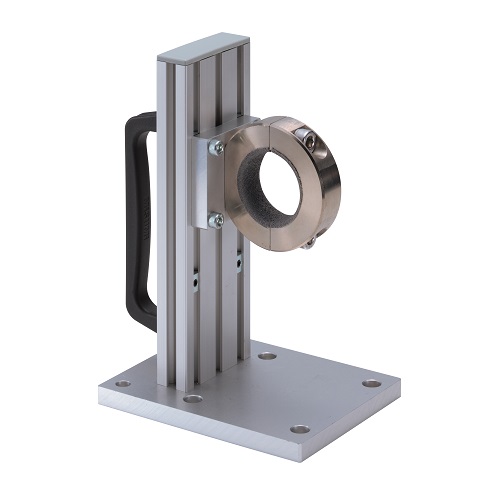

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

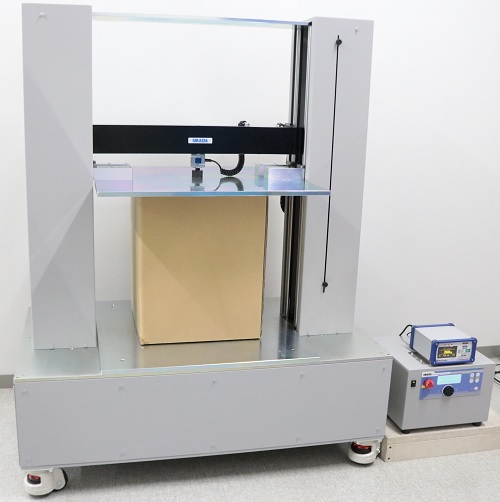

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

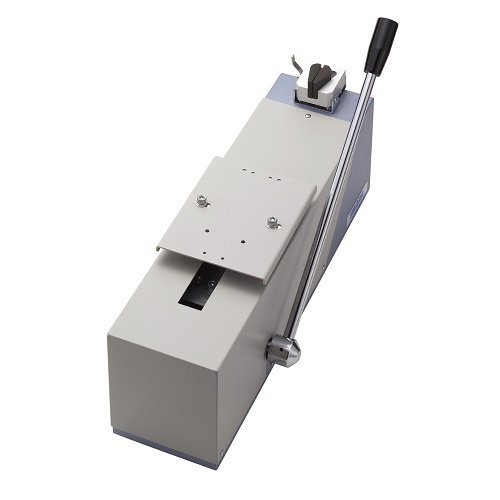

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

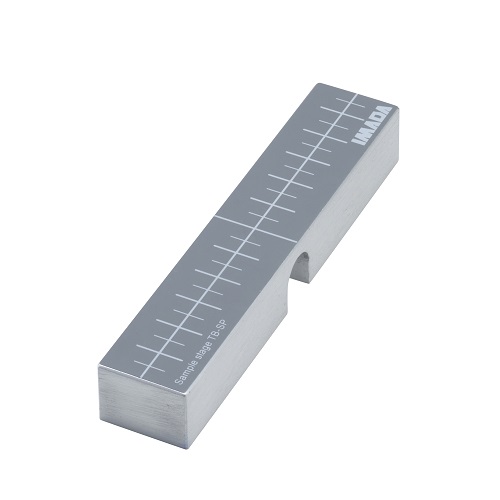

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

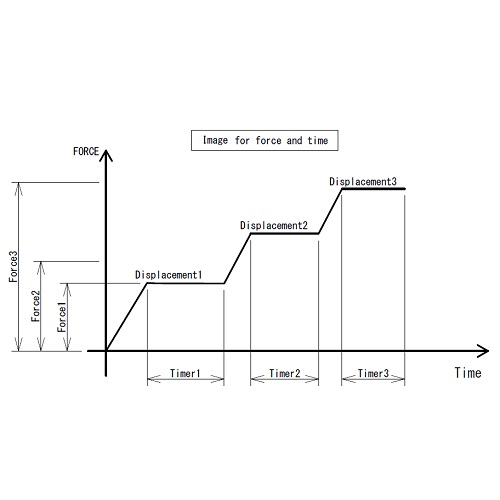

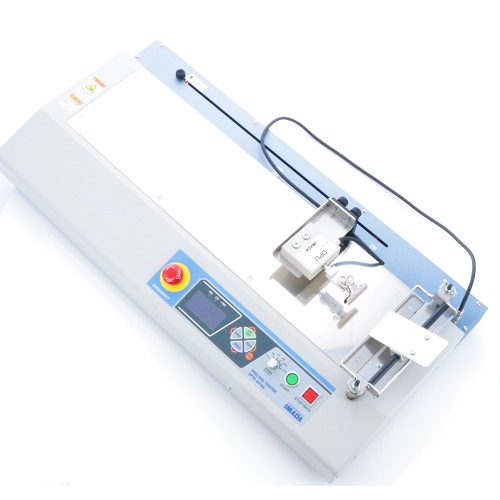

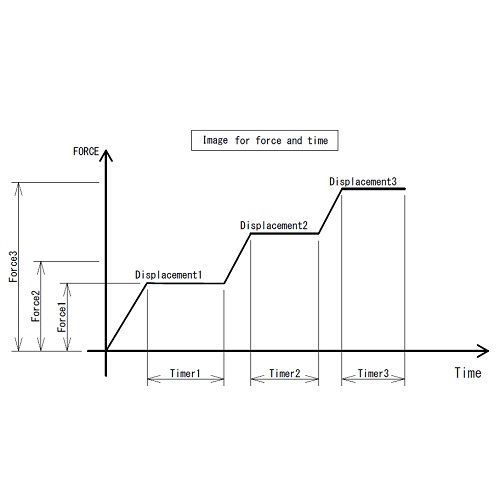

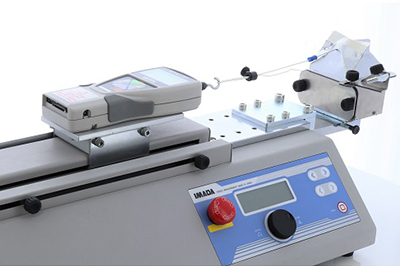

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

Visualized Film Chuck

Visualized Film Chuck

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

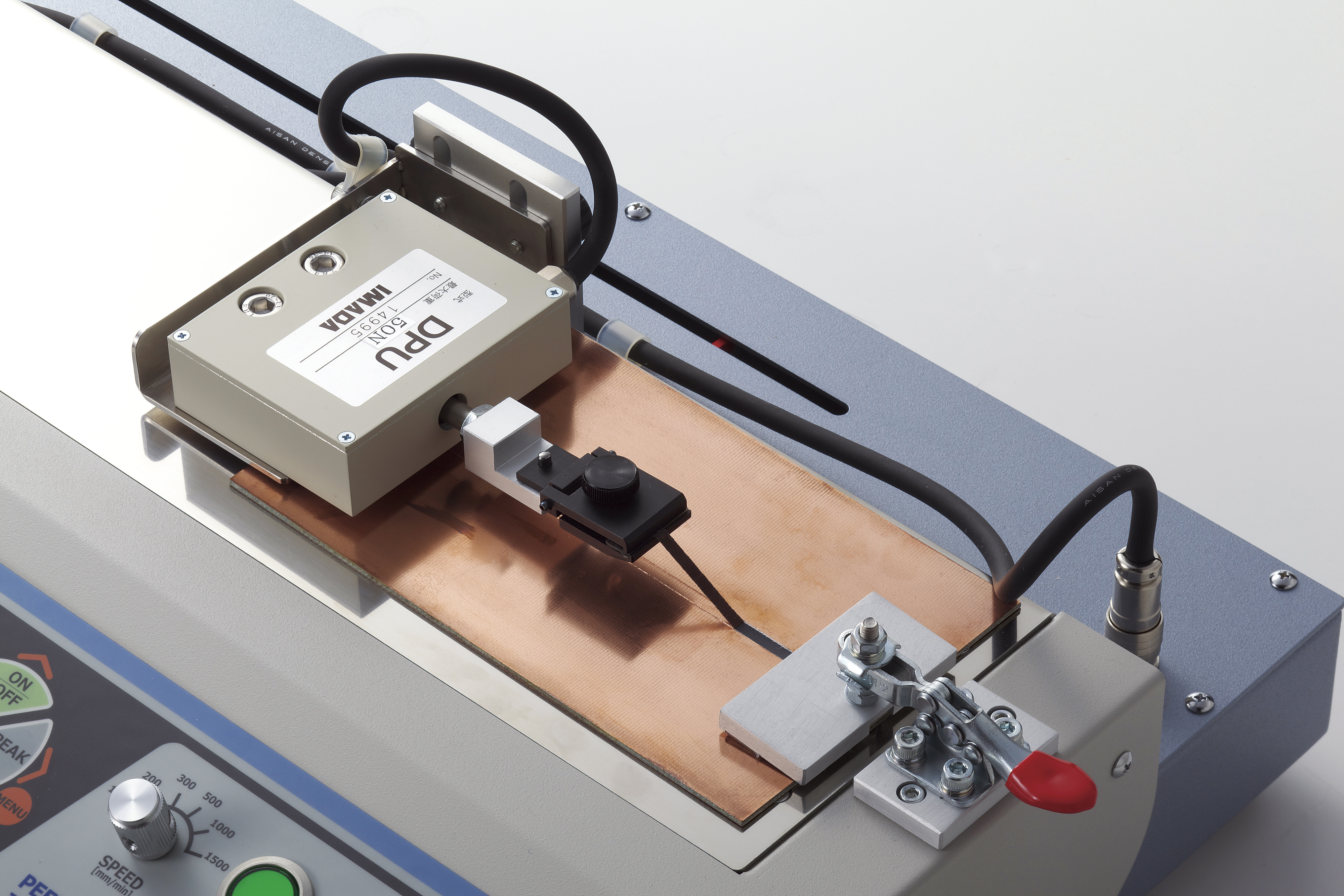

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)